Our

Capabilities

>99%

PRODUCT CONFORMANCE

80%

REPEAT BUSINESS

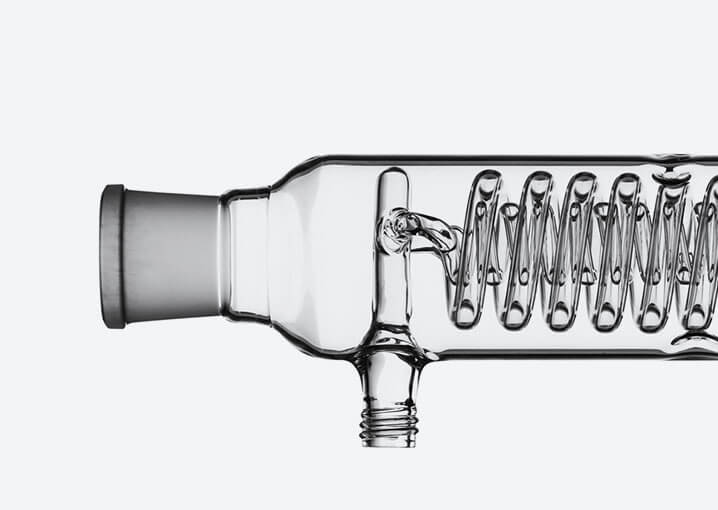

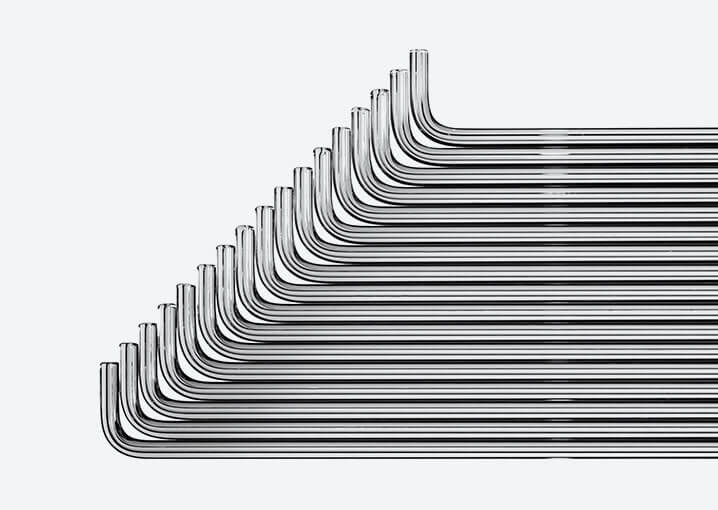

Outstanding glass engineering

We have unrivalled applications understanding; from scientific and industrial to interior design and architecture. Our technical team work closely with our customers to ensure that the custom glassware we manufacture will meet their often-complex specifications. Our highly-skilled team of glassblowers, coupled with the broadest range of precision processes and techniques, enables us to produce the highest quality of glassware and to reproduce designs reliably and consistently.

1

One of the UK’s most advanced glassblowing facilities

200+

Combined years of experience

100k+

OEM products manufactured every year

500

Loyal customers benefit from our capabilities

Helping you to get the best in customised technical glass

From the first point of contact, our team of glass specialists will help you to define the achievable tolerances and overall specifications of your custom glassware. This consultation often results in a simplified manufacturing process; helping to reduce costs, improve product quality and durability, and increase final product performance.

Made in the UK

Glass Solutions is an expert manufacturer of custom precision engineered borosilicate glass components for scientific instrument manufacturers and designers throughout the UK.

All of our raw materials are manufactured in Europe and are of the highest quality, conforming to ISO 3585 standard. View custom glassware.